NewGen Surgical Introduces Sustainably Designed Needle Counter

San Rafael, California, November 28, 2017 – NewGen Surgical, Inc. announced the release of a new product line, NewGen Surgical Needle Counters, the first sustainably designed single-use disposable needle counters. The NewGen Surgical Needle Counters are designed to deliver the same clinical performance using plant-based materials, while reducing the use of non-renewable plastics. Needle counters are present in almost all operating room (O.R.) procedures to account for and safely dispose of used surgical sharps.

San Rafael, California, November 28, 2017 – NewGen Surgical, Inc. announced the release of a new product line, NewGen Surgical Needle Counters, the first sustainably designed single-use disposable needle counters. The NewGen Surgical Needle Counters are designed to deliver the same clinical performance using plant-based materials, while reducing the use of non-renewable plastics. Needle counters are present in almost all operating room (O.R.) procedures to account for and safely dispose of used surgical sharps.

Per the 2016 Sustainability Benchmark Report from Practice Greenhealth, hospitals in the U.S. generate over 12,000 tons of waste per day; up to 30% from the O.R. The healthcare industry recognizes the connection between human health and the environment – and seek solutions from a variety of resources or processes to help counter their unhealthy contribution.

“Our customers have asked us to help them green their O.R. with single-use disposable products that create less plastic waste,” said Rob Chase, Founder and President of NewGen Surgical. “We are excited to offer a needle counter with the outer box achieving a 95% reduction of plastic waste, by weight, headed to landfills.”

“All plastic waste affects human health. There is no ‘away’ when it comes to plastic waste in our environment,” added Dr. Ann Blake, Environmental and Public Health Consulting. “Traditional surgical needle counter boxes are produced with high-impact polystyrene (HIPS) plastic. Because the material was used as a medical device, it is not a candidate to be recycled, and not readily biodegradable in a landfill. If incinerated, polystyrene produces a complex mixture of polycyclic aromatic hydrocarbons, shown to have negative impacts on public health.”

The NewGen Surgical Needle Counters have a direct and measurable impact in reducing plastic waste. If a hospital converts to NewGen Surgical Needle Counters, 1,000 pounds of plastic waste could be avoided from their O.R. for every 12,500 needle counters used.

“Healthcare systems with Environmentally Preferable Purchasing or EPP initiatives are embracing the sustainable innovation that enables them to deliver on their healthcare climate challenge commitment,” added Rob Chase. “Using NewGen Surgical products is not a one-time benefit, but a measurable avoidance of plastic waste – for each product – year after year. Really, it’s a way forward out of our dependence on single-use disposable plastic products. While the consumer market has moved in this direction, the medical device market is a more complicated space. After a period of development to ensure efficacy, performance and regulatory compliance, this second product line is available to help our customers looking for healthier product solutions – in a big way. Greening the O.R. one product at time is a team motto around our office. Just one healthcare system could avoid contributing several tons of plastic waste generated from their O.R. by switching to the same product made from sustainable material. That’s one system, one product.”

“We’ve been able to create another line of single-use surgical products using the same sustainable feedstock from the skin stapler line,” said NewGen Surgical Principal Engineer, Ken Blier. “Most importantly, the process used for the material complies with OSHA and ASTM F2132 requirements for sharps handling and puncture resistance, and our design has been patented by the United States Patent and Trademark Office.”

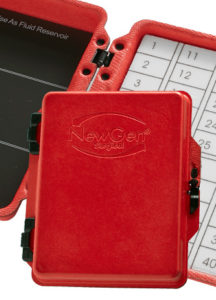

The NewGen Surgical Needle Counters are available in various foam and magnet combinations, a full-surface magnet for odd-shaped sharps, adhesive tabs to secure the needle counter to any workspace, is latex free, and features a secure closure latch with audible feedback. The initial NewGen Surgical Needle Counter product family includes 40 count foam/magnet, 60 count double magnet, and 80 count double foam configurations; single sterile or bulk, non-sterile for surgical procedure packs.